SANOVO TECHNOLOGY PROCESS – Denmark

SANOVO PROCESS SOLUTIONS

Datavej 3

5220 Odense SØ

Denmark

SANOVO Technology Group, Denmark

PES – Process Engineering Solutions, Chennai represent M/s Sanovo Technology Process, a 6 decades old company with Headquarters in Odense, Denmark who is the leading solution provider in setting up of Turnkey and processing plant. SANOVO TECHNOLOGY PROCESS (STP) is specialists within unique niche equipment of spray drying and Wave pasteurization for Extended Shelf life.

SPRAY DRYER

The only box dryer designed and manufactured in Europe

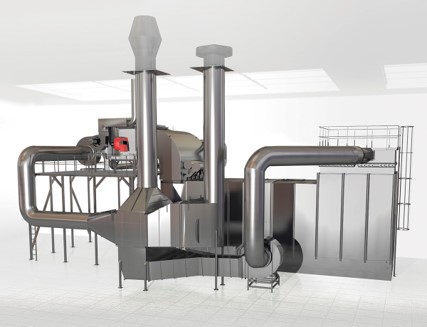

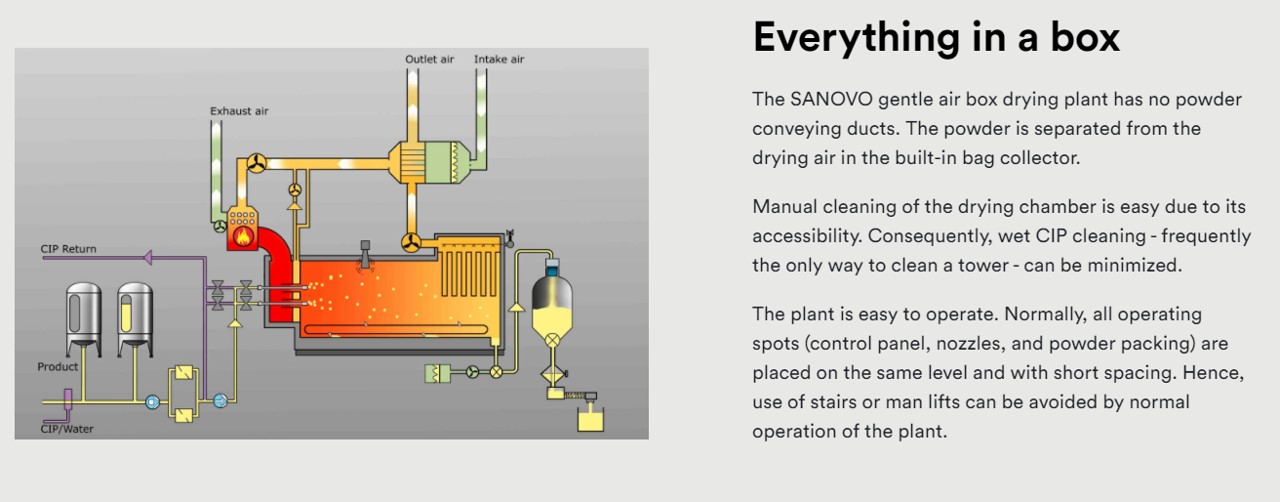

The SANOVO Gentle-Air box Spray Dryer can be used on a wide range of food or feed products ranging from animal by-product to plant proteins, among others. Producing a long-lasting shelf stable powder ingredient will bring more value and application opportunities when compared to unprocessed raw materials.

Various spray drying plant sizes are available with water evaporation capacity from 50 to 2500 kg/hour. This ensures suitability for new and innovative startup companies, as well as well-established larger powder producers.

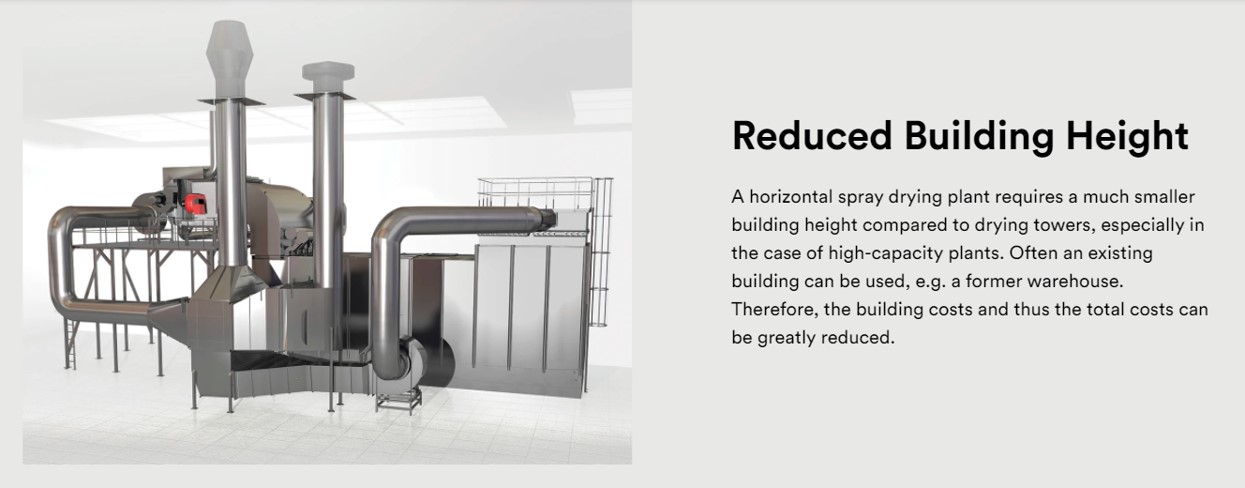

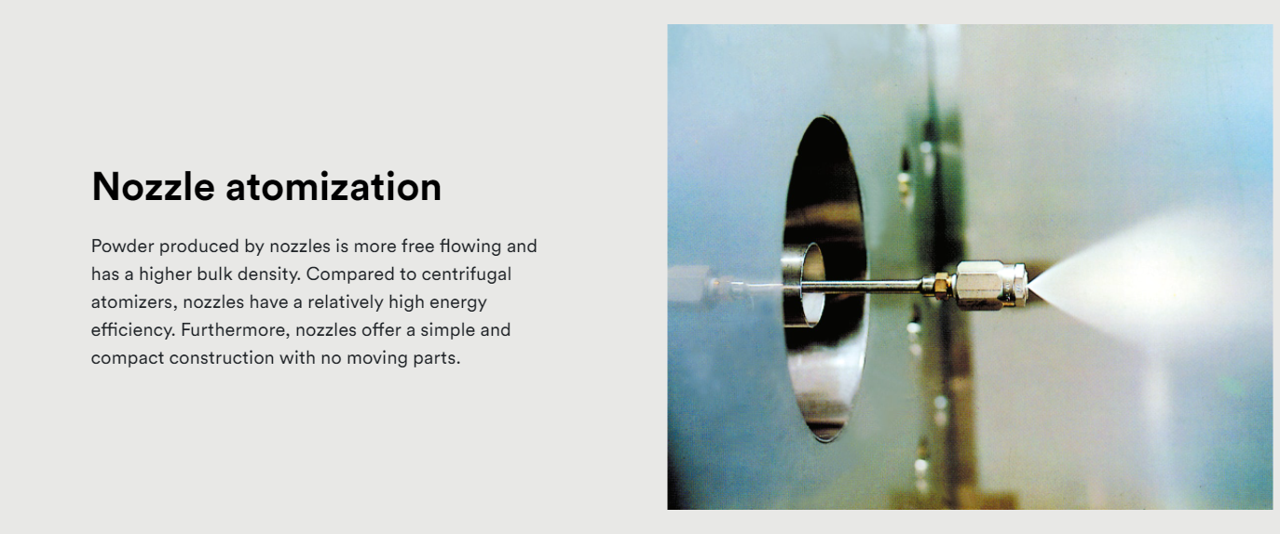

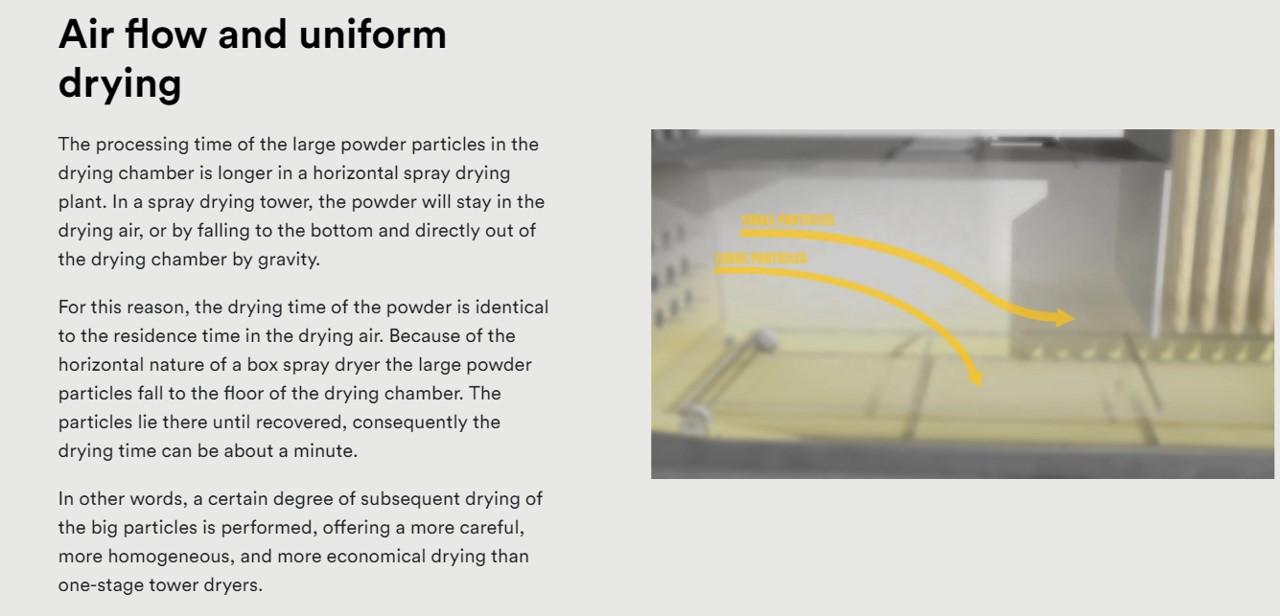

A box dryer differs from Spray drying towers by being horizontal and box shaped and therefore it is generally more compact and can often be installed in an existing building. Low CapEx, higher yield, nozzle atomization, easy operation and preserved product properties are just some of the unique product benefits of the SANOVO Gentle-Air box Spray Dryer.

SALIENT FEATURES OF SPRAY DRYER

APPLICATIONS OF SPRAY DRYER

Hydrolyzed fish, seaweed & algae

The sea is an enormous source of not yet utilized novel foods.

The SANOVO Gentle Air Box Dryer can be used to spray dry products from the more exotic algae protein to the traditional by-products like hydrolyzed fish proteins. Turning the very easily perishable marine products into a shelf stable powder significantly reduces waste, producing a healthy protein that can be used for human consumption or feed.

Spray Drying of Plant Proteins

Pulses, grass, seeds, pot ale and others are ingredients which can add protein enrichment and nutritional benefits to food and feet products. With a growing demand for vegan products, plant protein powder is a ideal business opportunity.

Plant proteins are an important part of the human diet, but traditionally proteins from plants have not been purified.

Isolating the plant proteins and drying them into a shelf stable powder will give you new products with endless possibilities. Pulses usually have a high content of protein, but also starch and fiber.

Other plant products, potato or grass have a lower protein content, but given the shear volume of grass you will have a vast good source. After purification and concentration the plant proteins can be spray dried giving you new types of proteins with interesting functionalities that can be used in human food or in animal feed.

Vegetables & Fruits

The waste of vegetables and fruits is enormous. There are many reasons why vegetables and fruits end as waste. It can be that the shelf life is too short or because the fruit or vegetable is too small or simply sub-standard and therefore it is not appealing to the consumer.

Buy extracting the juice from the fruit or vegetable you will have a nutritional vitamin riche product, but it has a very low shelf life and it is expensive to transport because of the high water content. Spray drying can turn fruit and vegetable juice into nutritional colorful shelf stable products that are easy to rehydrate and use for the consumer.

Spray Drying of Blood

Blood (Hemoglobin & plasma) from slaughter houses that can be used as a functional ingredient in food or for feed for example in pet food.

Blood can be dried as it is or it can be separated in to plasma and hemoglobin. The SANOVO Gentle Air Box Dryer is widely used for drying blood products. The flat floor of the box dryer makes it easy to go into the dryer to dry clean the box making it possible to switch from the almost black hemoglobin powder to the off-white colored plasma powder.

Novel Foods

Novel foods are growing. Everyone is talking about eating insects, but no one really does it yet. One reason could be insects are not appealing if you put them directly on your plate.

If the insects are processed into a liquid product and then spray dried this will give you a nutritious powder that can be used in most types of food without having the unappealing visual effect of worms wriggling on your plate or the thought of grasshopper legs getting stuck in your throat.

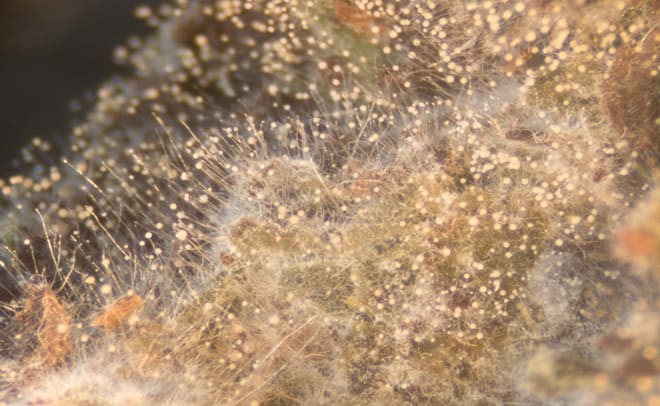

Yeast & Fungus

Yeast and fungus are usually grown in large fermentation tanks. After the fermentation the product can go directly to spray drying, or the slurry can be further processed.

The processing depends on the product. Do you desire yeast cells, whole yeast cells or yeast extract.

Gelatin, Collagen and Broth

Depending of the animal only about 60% is meat. The rest is intestines, blood, bone, skin, tendons and other things we do not normally eat.

Normally all parts of the animal is used for some kind of food or feed, for example as bone meal. By refining and hydrolyzing collagen or gelatin from the abattoir you can produce a product that is more bioavailable and has a better nutritional value and therefore has a higher value. Spray drying of the high value proteins ensures that the product quality is sustained and a good solubility of the powder gives you a consumer friendly product.

WAVE PASTEURIZER

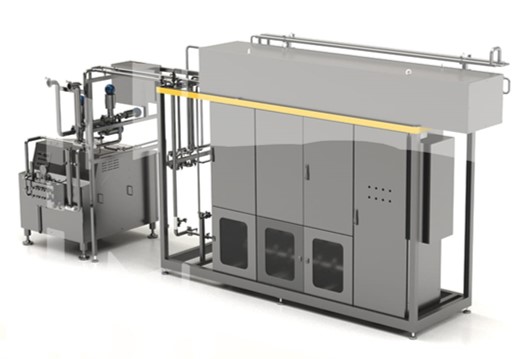

SANOVO’s patented WAVE Technology, is a system that applies a high frequency / high voltage electrical fields to the liquid product.

The WAVE Technology significantly extends your liquid product shelf life with its innovative heat treatment method. The machine is available in capacities between 1.000 – 10.000 liters/hour and works with every SANOVO Pasteurizer. Not sure about the impact on your product? No problem. Our test plant is ready for testing. SANOVO WAVE Technology works with pulsed ohmic heating to increase shelf life without denaturation of the product.

SALIENT FEATURES OF WAVE PASTEURIZER

This method is based on three key principles: speed, precision, and uniformity. The high temperature applied requires a short holding time of the product, so speed is decisive. The temperature is close to the denaturation limit, so we need high precision. Lastly, both heating and holding time are short, so the product must be uniformly heated.

WAVE Technology performs with industry-leading electrical efficiency and allows liquid food producers to sell safe, highly competitive products of consistent quality to a larger customer base.

The heat is generated by interactions between the moving particles that form the current and the ions that composed the product, so stressing bacteria without compromising the functionality property.

The SANOVO WAVE Technology instantaneously transfers a huge quantity of energy in a fraction of a second. The energy is transferred to the entire product mass allowing a uniform heating. As the product is heated directly by the kinetic energy, it allows product heating up just below the coagulation point. It is a stand-alone apparatus that can be joined to every configuration of pasteurizers. It does not influence or change the pre-existing process

APPLICATIONS OF WAVE PASTEURIZER

Nutritional Drinks

WAVE pasteurization applied to a jelly amino acid mixture based sport drink is giving a longest Shelf Life without any reduction of the functional properties.

When WAVE pasteurization is applied on jelly nutritional drinks, we achieve an increase of the pasteurization temperature which lead to a higher killing rate with a consequent enhancement of the shelf life. These types of drinks, treated with conventional systems, normally result with a kind of burnt taste which WAVE pasteurization succeeds in removing.

In addition, WAVE pasteurization allow the product to be thermally treated with limited damage to the amino acids, meaning that the treated product has less denatured proteins, therefore keeping their functional characteristics.

Vegetal based drinks

In plant-based drinks processing, where the direct heating sterilization methods are already recognized and accepted as the solution to be adopted, Wave pasteurization, leads to further improvements.

Vegetal based drinks

When WAVE pasteurization is applied on rice drinks, we obtain a treated product with a better color (More white and brilliant) due to the reduction of Maillard reaction, a less cooked savor, thanks to the presence of oil in the product that is not effect by the WAVE action. In addition, the taste of the rice drink is sweeter, and the texture is better.

When Wave pasteurization is applied on almond milk, the treated product flavor is very close to the raw product. Moreover, this technology keeps the electrical charges of the proteins, reducing their denaturation, therefore decreasing the sedimentation of the product.

Fruits & Colorants

Sterilization of fruit nectars with WAVE preserves all the physical characteristics of the product keeping the original color and taste.

Pear juice, as many other fruit juices, is pasteurized with conventional methods with some drawbacks on its properties. Pear juice color tent to become darker during pasteurization.

Fruit defined as “red” (strawberry, raspberry, red orange etc.) are very sensitive to temperature effects, especially color changes are related to thermal damages.

The damages are caused by the oxidation enzymes that act during the heating phase, especially when the temperature is high. With WAVE, juices can maintain their nutrient components and not decolorate the red juices (orange, blueberries, berries, blackberries, etc.)

Animal Blood

The WAVE pasteurization grants a significant increase of the pasteurization temperature and a decrease of the product degradation.

In animal blood applications, ohmic heating leads to a significant increase of the pasteurization temperature, reducing the fouling phenomena, thus decreasing the product degradation and stability of the treated product.

Tests on the pasteurization of animal blood have highlighted a tremendous killing rate: 9 Log. Reductions for Salmonella spp. And 7 Log. Reductions for Clostridium Perfrigens.

Fruit Puree

Application of the WAVE pasteurization/sterilization of fruit purees ensures the uniform heating of the product in a very short time avoiding overheating phenomena due to the indirect heating.

Fruit purees are very difficult to pasteurize/sterilize because of their viscosity. The high viscosity makes the uniform heating of the entire product very difficult in a short amount of time.

To be sure of the uniformity of the heating tubular heat exchangers are used, but the high pressure drops in the pipes limit the speed of the product in the system with unavoidable over-heating of the surface of the product flowing in the pipes.

The WAVE is heating instantaneously and uniformly the product in a short pipe ensuing the best sterilization/pasteurization process.

Ice Cream Bases

The WAVE pasteurization applied in a process for UHT mixes for artisan ice-cream production is giving the possibility to sterilize the product at a higher temperature and reduce the Maillard reaction.

The UHT base or mix for production of artisanal ice cream is a difficult product to sterilize due to its high sugar content, which emphasizes the thermal damage caused by conventional UHT processes. Wave sterilization guarantees a less denatured treated product (due to the lower coagulation of the proteins) and a better control of the Maillard reaction (less product yellowing).

Furthermore, it allows the production of ice cream bases with significantly higher soluble solid residues, guaranteeing to obtain a very creamy and full-bodied flavor ice creams.