FASA AB – Lithuania

FASA AB,

Stoties str. 8E, Marijampole LT-68112, Lithuania

Factory address: Stoties str. 10, Marijampole,LT-68112, Lithuania

PES represent FASA in South & East India market

About FASA Packaging Technology

FASA AB company manufactures processing, filling and packaging equipment for dairy products. Since 1959 the manufacture has huge experience in packaging field and it is well known in dairy industry all over the world.

We improve, change, listen to the needs and observations of our customers every day. Today we can proudly say that 99 % of our products are exported. We sell in more than 85 countries of all 6 continents: Europe, North America, South America, Africa, Asia, Australia.

Fasa equipment is designed for butter, margarine, processed cheese and glazed curd cheese. We offer reliable machines for small and medium dairy plants. We produce equipment processing to assembly.

FILLING AND WRAPPING

ARM – Butter filling and wrapping machine:

ARM is designed to fill and wrap butter, margarine, curd and other edible fats in aluminum foil, parchment paper or ecoline. Two product feeding options: hopper with augers or direct feeding from processing line.

Dosing range:

- 9-25 g / up to 80 packs/min

- 50-125 g / up to 70 packs/min

- 100-250 g / up to 70 packs/min

- 250-500 g / up to 40 packs/min

- 500-1000 g / up to 20 packs/min

- Dimensions: (L x W x H) ~ 1730 x 2300 x 2030 mm

ARM B2/B3 – Butter filling and wrapping machine

ARM is designed to fi ll and wrap butter, margarine and other edible fats in aluminum foil, parchment paper or ecoline. The upgraded ARM is more convenient for the operator: it has an integrated lubrication system, partial CIP option, quicker and more comfortable package height change adjustment, easier to change a roll.

Dosing range:

- ARM-B2 100-250 g / up to 70 packs/min

- ARM-B3 250-500 g / up to 40 packs/min

- Dimensions: (L x W x H) ~ 2880 x 2700 x 2050 mm

ARU – Processes cheese filling and wrapping machine

ARU – automatic packaging machine for foiling and heat-sealing of processed and cream cheese with aluminum foil with or without easy opening system and labeling.

- Dosing range: 15 – 100 g

- Maximum output: up to 50 packs/min

- Dimensions: (L x W x H) ~ 2800 x 1480 x 1760 mm

AR6U – Processed cheese packaging, cartooning machine

AR6U – automatic packaging machine for foiling and heat-sealing of processed and cream cheese with aluminum foil and packing into individual carton.

- Dosing range: 180, 200, 250 g

- Maximum output: up to 30 packs/min

- Dimensions: (L x W x H) ~ 2600 x 1700 x 1800 mm

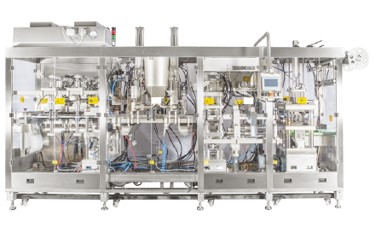

TFM – Thermoforming Machine

TFM – fully automatic packaging machine designed to form cups, fill them with paste-type products as butter, margarine, processed cheese, sour cream, yogurt, etc., and seal the filled cups with aluminum foil lids.

- Dosing range: 10-1000 g

- Maximum output: 1920-28800 packs/h

- Dimensions: (L x W x H)~ 6000 x 1100 x 2100 mm

RFS 40 – Rotary tub filling, sealing and closing machine

RFS 40 – designed for packing paste type products as butter, margarine, spreads, curd dessert in pre-made cups, containers.

- Dosing range: 200-1000 g

- Maximum output: up to 40 packs/min

- Dimensions: (L x W x H) ~ 4260 x 2455 x 1900 mm

DSU – Butter Case Packer

DSU – semi-automatic cartoning machine used for grouping and stacking of butter bricks packed with ARM and other wrapping machine.

- Maximum output: up to 100 packs/min

- Dimensions: (L x W x H) ~ 1930 x 1200 x 1400 mm

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

PROCESSING EQUIPMENTS

SLP – Butter Block Cutting Machine

SLP is designed to cut 10-25 kg butter blocks into small pieces before homogenizing and repackaging of butter.

Butter block size:

up to 420 x 310 x 340 mm

Product temperature: +4….+8 °C

Maximum output: up to 1900 kg/h

Dimensions: (L x W x H) ~ 2240 x 723 x 2300 mm

BH – Butter Homogenizer

BH homogenizer is designed to homogenize bulk butter before repackaging. Robust design allows reprocessing cooled butter blocks, the temperature of which is 0°C. Exceptional feature of BH homogenizer is the CIP system.

Input temperature: 0….+10 °C

Maximum output: 800-2000 kg/h

Dimensions: (L x W x H) ~ 1991 x 1012 x 1619 mm